Supply Chain Management

A supply chain can be seen as a network of organizations working together to fulfill customer orders. It is a flow of materials, information and services. Effective supply chain management and logistics can provide an organization with competitive advantage.

With our modern vision on packaging management, we would like to play a role within your supply chain management, as a part of the overall process and therefore we will focus further below on the subject of ‘packaging’.

If we look at the most common purchasing model of packaging, the general conclusion is that it is arranged in such a way that you are expected to have all kinds of amenities. And you will also be expected to structurally provide the (often expensive) facilities to the benefit of your packaging suppliers. The basic amenities that you will need are:

- A fully equipped and furnished warehouse

- People 'staffing and managing' that warehouse

- Sufficient liquidity and working capital to structurally (continue to) finance that warehouse including all existing equipment and including stocks

This way, all your different suppliers can deliver in accordance with their standard delivery time and in the agreed quantities. Often these quantities are mainly determined by minimum production sizes and often cover the need from a few weeks to a few months. By the time the packaging reaches the filling line, it has become about 25% more expensive on average.

After all, you have to stock it somewhere (space), someone has to handle it (labour costs) and often does so with equipment such as forklifts (bought or leased), place the supplies on the storage racks (purchased). Then it stands on call in your warehouse until your production will use it. If you are going to use it, then someone (labour costs) has to pick the items once again with a forklift from the storage racks and deliver them to the appropriate production site and/or filling station (internal handling and logistics).

Furthermore, the money invested in that stock is blocked capital (and creates loss of interest, also defined as cost of capital) and cannot be used for other purposes.

In short, before the packaging is actually used it has already generated a lot of costs. In this traditional model, these costs are seen as inevitable and therefore taken for granted. In the demand oriented model, as we organize the packaging management for our customers, we see above costs as wasteful and avoidable.

With our contribution the packaging management of your supply chain will transform more and more towards a value chain with lean management characteristics.

Our goals in creating a value chain for your organization are fourfold:

- Reduction of lead time

- Improving the delivery reliability

- Increase flexibility

- Reduction of integral costs

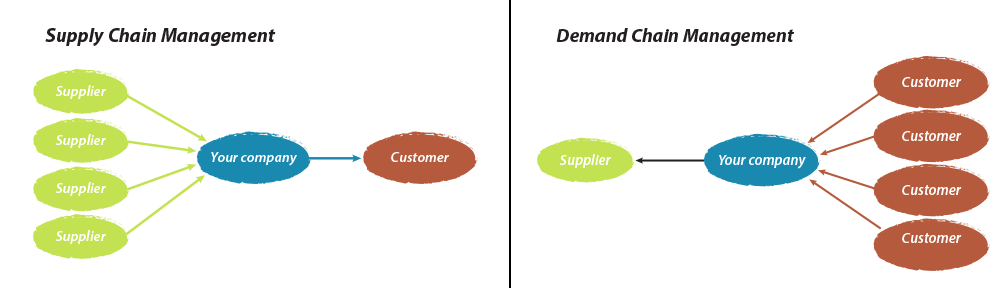

We therefore describe the demand-oriented approach such as we adhere, as Demand Chain Management. The routine traditional model is mainly supply-driven.

We believe that your production process and the correlative consequences should be guided by your customers and not by your suppliers.

However, that means that it is necessary to have a group of suppliers that can facilitate you on all counts in the process.

Or you leave it to a partner who has the knowledge and infrastructure to (re)structure your organization in terms of packaging management.